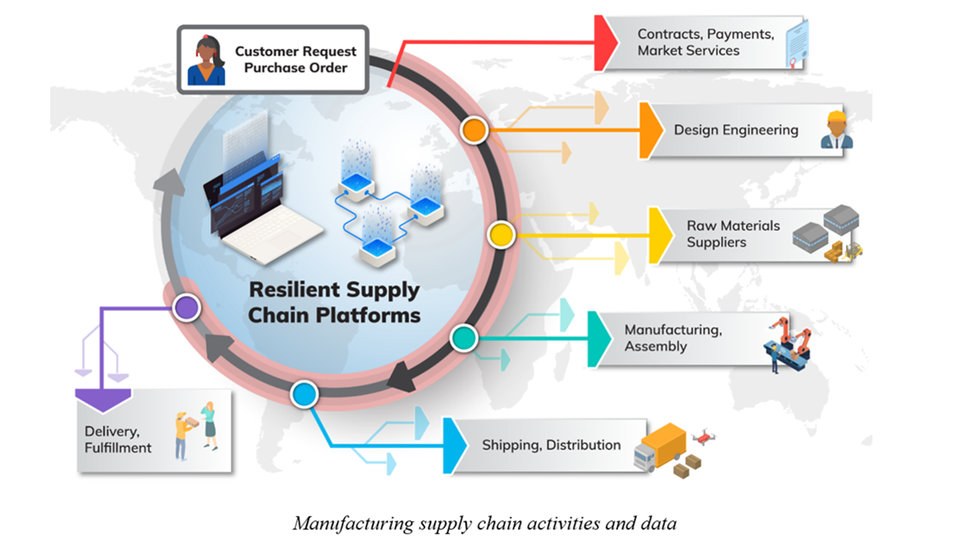

Blockchain technology is transforming the way that businesses operate, and supply chain management is no exception. Blockchain has the potential to make supply chains more transparent, traceable, and sustainable.

What is blockchain?

Blockchain is a distributed ledger technology that can be used to record transactions in a secure and tamper-proof way. It is best known for its role in powering cryptocurrencies, but it has the potential to be used in a wide range of other applications, including supply chain management.

How can blockchain be used for ethical and sustainable supply chains?

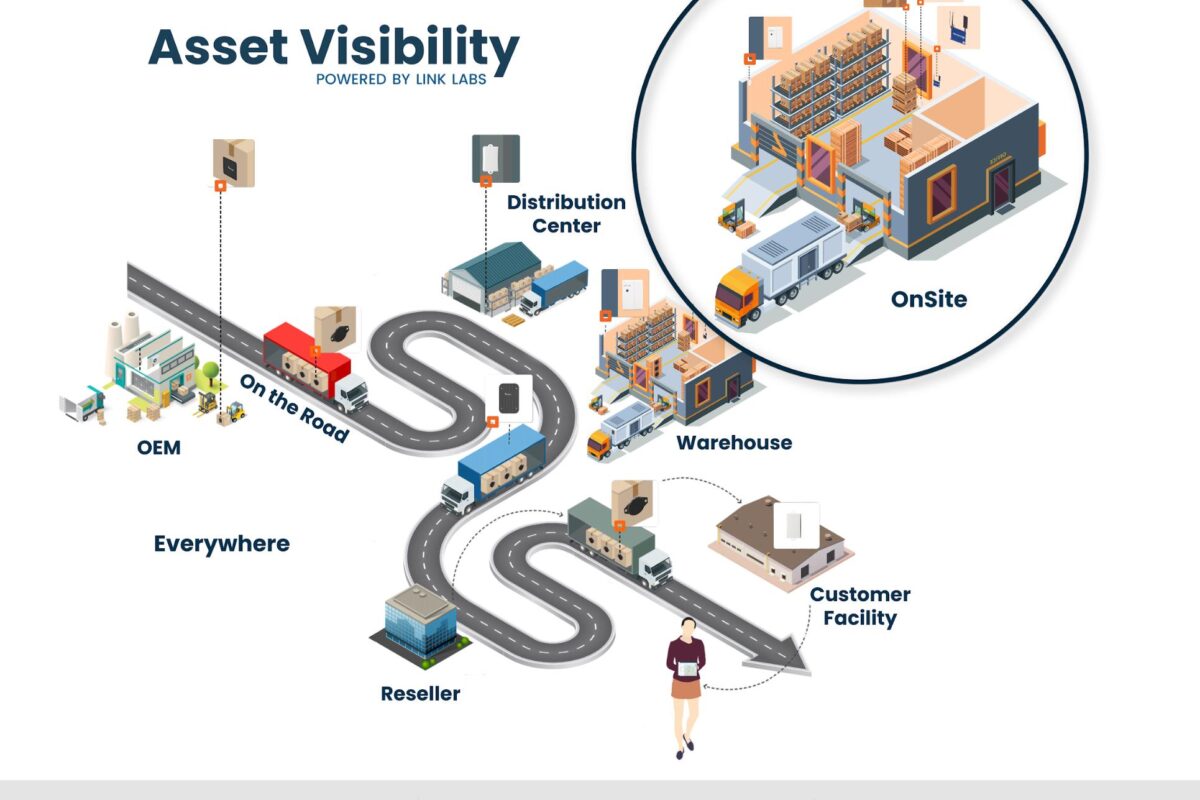

Blockchain can be used to track the provenance of products, from raw materials to finished goods. This can help to ensure that products are sourced ethically and sustainably and that they are not counterfeit.

For example, a company could use blockchain to track the supply chain of its coffee beans. The blockchain would record the origin of the beans, the farmers who grew them, and the processing and transportation companies that handled them. This would allow the company to verify that its coffee is sourced from sustainable farms and that it has not been tampered with along the way.

Blockchain can also be used to promote ethical labor practices in supply chains. For example, a company could use blockchain to track the working conditions of its suppliers’ factories. This would allow the company to identify and address any potential labor abuses.

In addition, blockchain can be used to improve the traceability of food products. This can help to ensure food safety and prevent foodborne illness outbreaks. For example, a company could use blockchain to track the movement of food products through its supply chain. This would allow the company to quickly identify and recall any contaminated products.

Benefits of using blockchain for ethical and sustainable supply chains

There are several benefits to using blockchain for ethical and sustainable supply chains, including:

- Increased transparency: Blockchain can make supply chains more transparent by providing a tamper-proof record of all transactions. This can help to reduce fraud and corruption.

- Improved traceability: Blockchain can help to improve the traceability of products, from raw materials to finished goods. This can help to ensure that products are sourced ethically and sustainably and that they are not counterfeit.

- Enhanced food safety: Blockchain can help to enhance food safety by providing a way to track the movement of food products through the supply chain. This can help to quickly identify and recall any contaminated products.

- Reduced environmental impact: Blockchain can help to reduce the environmental impact of supply chains by making it easier to track and manage resources. For example, companies can use blockchain to track the carbon footprint of their products.

Challenges of using blockchain for ethical and sustainable supply chains

There are also some challenges associated with using blockchain for ethical and sustainable supply chains, including:

- Cost: Blockchain technology can be expensive to implement and maintain.

- Complexity: Blockchain technology can be complex to understand and implement.

- Lack of standardization: There is currently a lack of standardization around blockchain technology, which can make it difficult to implement and integrate with other systems.

- Regulatory uncertainty: There is currently some regulatory uncertainty around blockchain technology.

What are some examples of companies that are using blockchain for ethical and sustainable supply chains?

- IBM and Walmart: IBM and Walmart are working together to use blockchain to track the provenance of food products.

- Pfizer and MediLedger Network: Pfizer and MediLedger Network are using blockchain to prevent counterfeit drugs.

- Unilever and IBM: Unilever and IBM are using blockchain to promote sustainable palm oil production.

- IBM and Everledger: IBM and Everledger are using blockchain to track the supply chain of diamonds, from mine to market.

- BHP and IBM: BHP and IBM are using blockchain to improve the efficiency and transparency of the iron ore supply chain.

As blockchain technology continues to mature and become more widely adopted, we can expect to see more innovative and impactful applications in this area and more companies using the technology to improve the sustainability and ethics of their supply chains.

What steps can companies take to get started with using blockchain in their supply chain?

- Educate themselves about blockchain technology. There are a number of resources available online that can help companies to learn more about blockchain technology. Companies can also attend industry events or hire consultants to help them understand blockchain and its potential applications in their supply chain.

- Identify the specific areas of their supply chain where blockchain could be used to improve efficiency, transparency, or sustainability. Once companies have a good understanding of blockchain technology, they can start to identify specific areas of their supply chain where it could be used to make improvements.

- Pilot a blockchain project. Once companies have identified specific use cases for blockchain in their supply chain, they can start to pilot a project. This will help them to learn more about the process of implementing blockchain and to identify any potential challenges.

- Scale up the blockchain project. Once companies have successfully piloted a blockchain project, they can start to scale it up to other areas of their supply chain.

Here are some additional tips for getting started with blockchain technology:

- Start small: Don’t try to implement blockchain across your entire supply chain all at once. Start with a small pilot project and learn as you go.

- Partner with other companies: Blockchain is a collaborative technology. Partnering with other companies in your supply chain can help you to share costs and resources, and to create a more effective blockchain solution.

- Use a managed blockchain service: There are a number of companies that offer managed blockchain services. This can be a good option for companies that don’t have the expertise or resources to manage their own blockchain network.

What are some of the blockchain technologies that can be used for the supply chain?

- Hedera Hashgraph: Hedera is a public blockchain platform that is designed for enterprise use to be fast, secure, cost-effective, and scalable. It uses a unique consensus mechanism called Hashgraph, which allows it to process transactions at a high rate without sacrificing security or decentralization. Hedera is well-suited for supply chain management because it can handle large volumes of transactions quickly and securely.

- Hyperledger Fabric: Hyperledger Fabric is a permissioned blockchain platform that is also designed for enterprise use. It is highly scalable and secure, and it offers a variety of features that make it well-suited for supply chain management, including private channels, confidential transactions, and support for multiple smart contract languages.

- IBM Food Trust: IBM Food Trust is a blockchain-based platform that is designed to improve the traceability and transparency of food supply chains. It allows food companies to track the movement of food products from farm to fork, and it provides consumers with information about the origin and quality of their food.

- VeChainThor: VeChainThor is a public blockchain platform that is designed to improve the transparency of supply chains. It uses a variety of technologies, including RFID tags and IoT devices, to track the movement of goods and products.

- Everledger: Everledger is a blockchain-based platform that is used to track the provenance of diamonds and other high-value assets. It allows businesses to verify the authenticity of their products and to track their movement through the supply chain.

Where can I read more?

Here are some resources companies can use to get started with blockchain:

- Blockchain for Supply Chain Management: A Comprehensive Guide by IBM

- Blockchain for Supply Chain: A Practical Guide by Deloitte

- Blockchain for Supply Chain Transparency and Traceability by Amazon Web Services

- Supply Chain Blockchain Consortium

We recommend that companies learn more about blockchain and how it can be used to improve supply chains. Blockchain is a transformative technology that has the potential to make supply chains more ethical, sustainable, and transparent. Companies that are early adopters of blockchain will be well-positioned to reap the rewards of this technology.